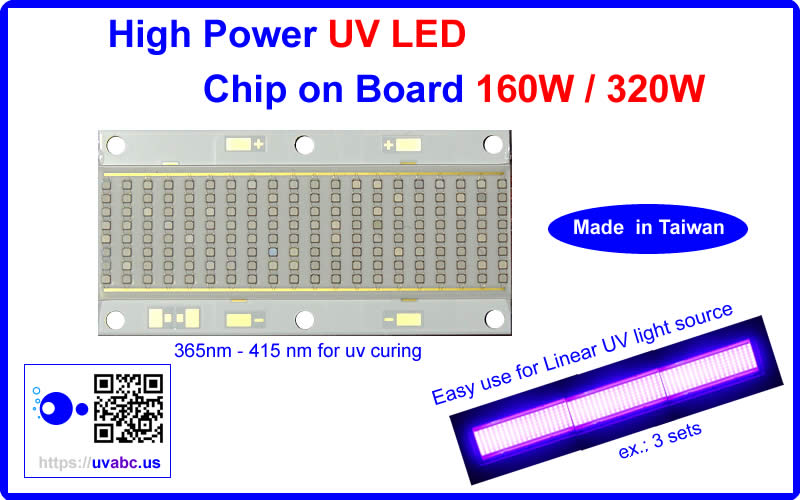

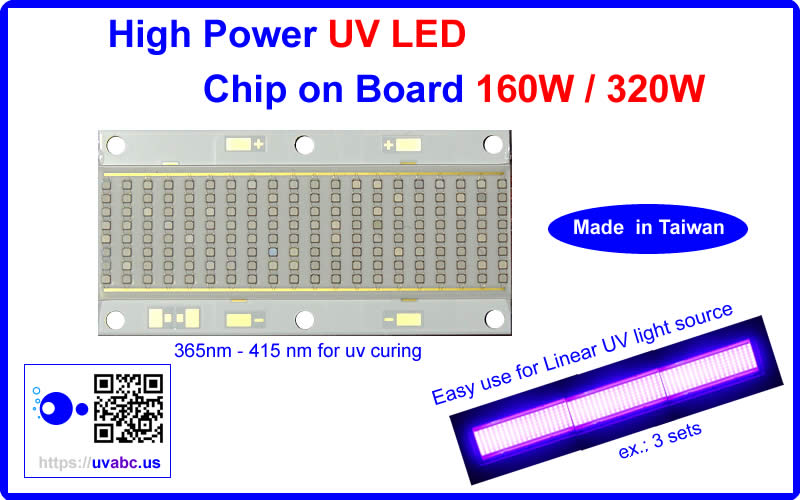

High Power UV LED module/lamp

( 160W G2 Ultimate - COB type )

UVA 365nm - 405nm

Key Features

- Board dimension of 56mm x 28mm, Basic power 160W With fine heat dissipation, able to scale 320W (Need more cooling).

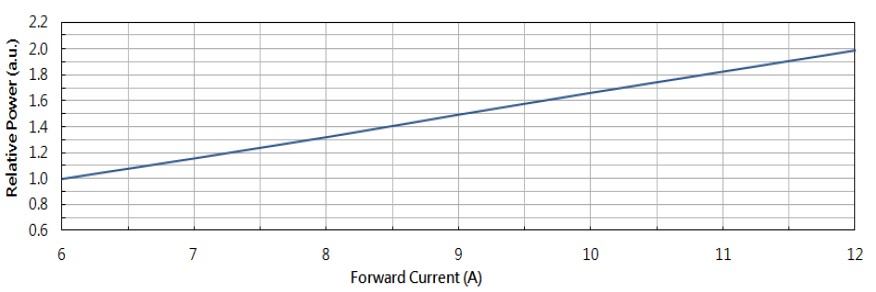

- Irradiation intensity scales high at higher current! (> 6 A operation) with High thermal conductivity package.

- Environmentally friendly: RoHS compliant, mercury-free.

- Variable drive currents: less than 4.5A through 12A or higher.

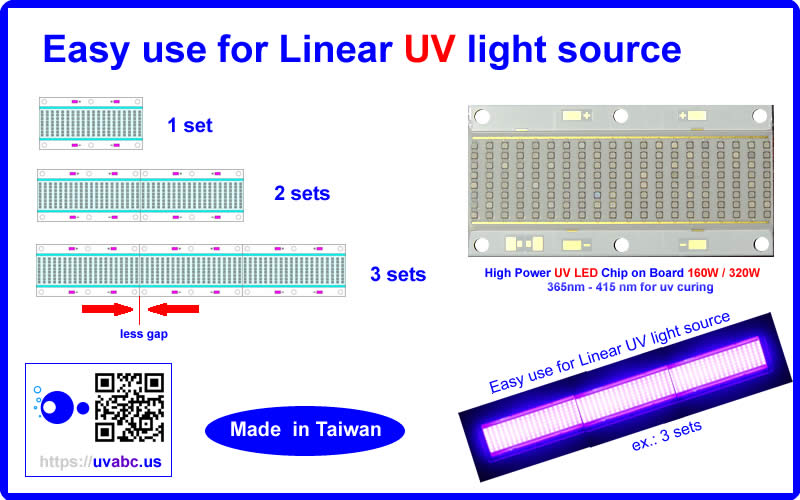

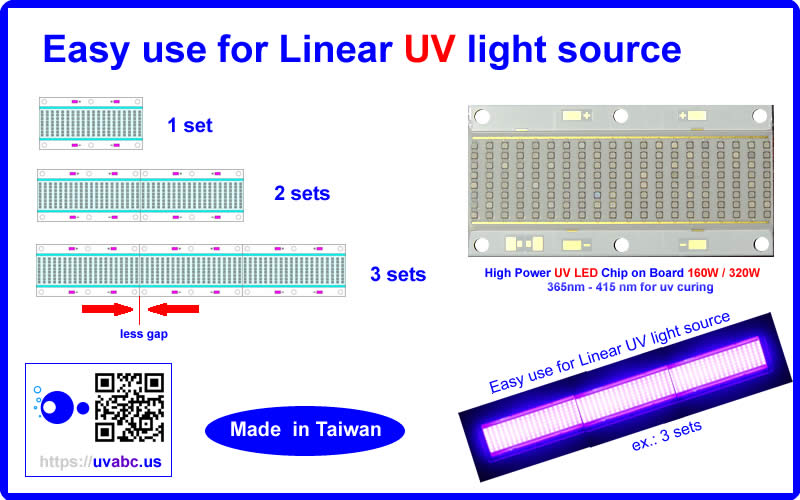

- Easy use for Linear UV light source.

- 395nm irradiation intensity 8W/cm2 ~ 11W/cm2

- 365nm irradiation intensity 4W/cm2 ~ 5W/cm2

Easy use for Linear UV light source

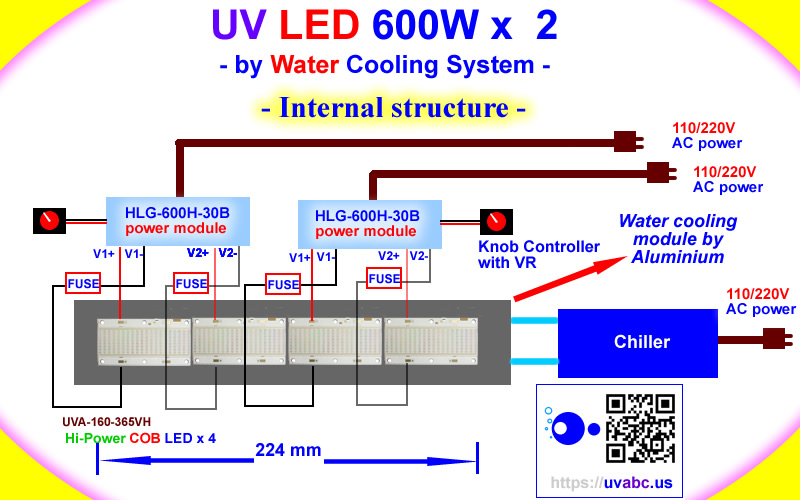

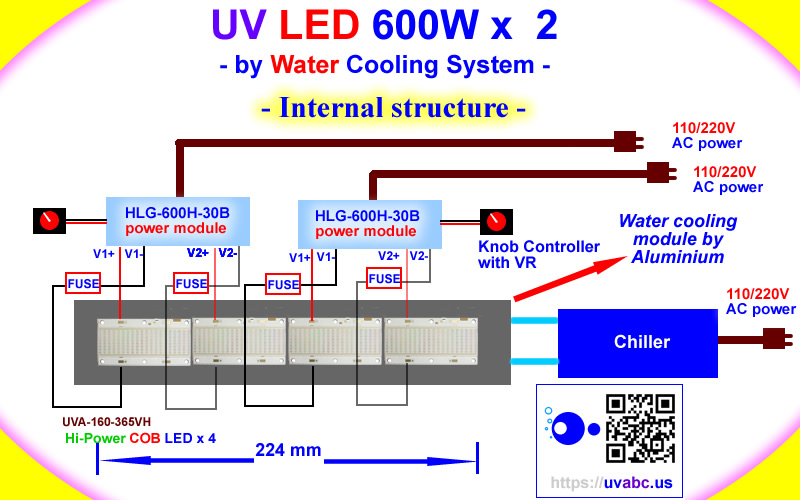

How to install the UV LED unit into modules?

You must need:

1.) Air/Water cooling heat sink:

The lower temperature you maintain on the COB board,the more intensity power you can run up to, along with longer life span.

2.) UV LED power driver

It's better with dimming function, but must be constant current supply.

The Easiest installation Powerful High Power Board to Start UV LED Curing !

Our customer’s project for reference !!

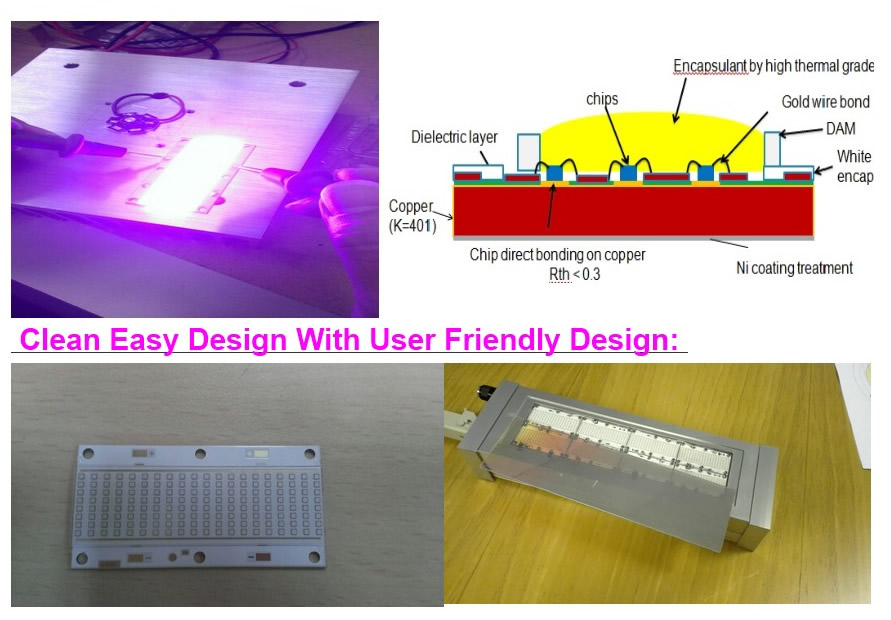

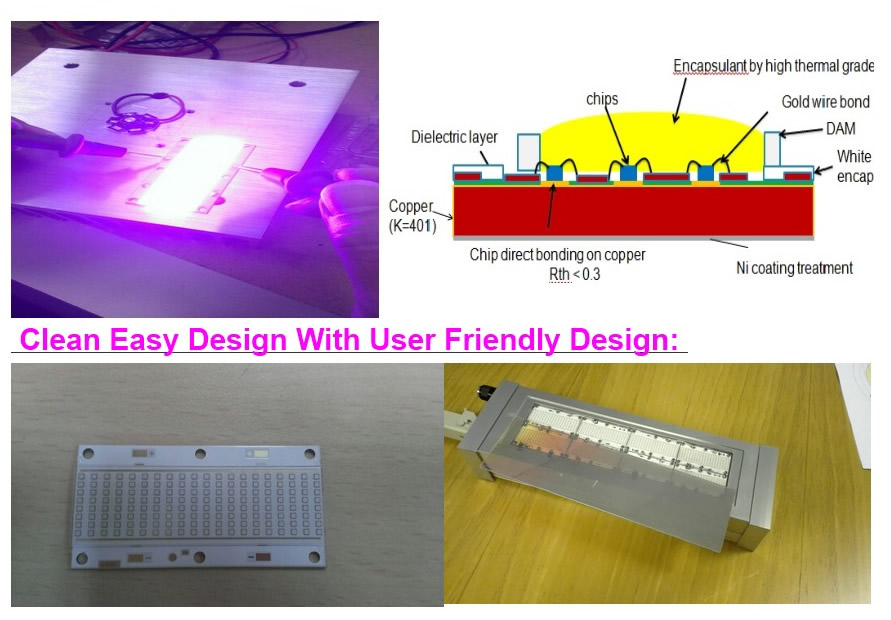

Technology of Overviews

The Multi-chips LED package benefit from innovations in device technology, chip package and thermalmanagement. This suite of technologies give engineers and system designers the freedom to develop solutions both high in power and efficiency.

- The Technology -

Our technology enables to emit large area photons uniformly over the entire COB UV LED surface. The intense optical power density produced by these multi-chips facilitate designs which replace mercury lamps where arrays of traditional power LEDs cannot.

For UV devices, the side-less structure to let the engineers easy to design the linear UV LED light source and instead of the linear mercury lamps with power density 80W/cm -120W/cm.

- Packaging Technology -

Thermal management is critical in high power LED applications. The UV LEDs have the lowest thermal resistance of any LED on the market with a thermal resistance from junction to heat sink of 0.3°C/W or 0.35°C/W. This allows the LED to be driven at higher current densities while maintaining a low junction temperature, thereby resulting in brighter solutions and longer lifetimes.

- Reliability Technology -

Designed from the ground up, the COB Multi-chips LEDs are one of the most reliable light sources in the world today. COB Multi-chips LEDs have passed a rigorous suite of environmental and mechanical stress tests, including mechanical shock, vibration, temperature cycling and humidity, and high current applications. With very low failure rates and median lifetimes that typically exceed 10,000 hours, the COB Multi-chips LEDs are ready for evern the most demanding applications.

- Environmental Benefits -

Our LEDs help reduce power consumption and the amount of hazardous waste entering the environment. All COB Multi-chips LED products manufactured by us are RoHS compliant and free fo hazardous materials, including lead and mercury.

The Advantages of COB Multi-chips LEDs

Every LED is fully designed to ensure that it meets the high quality standards expected from our products.

>>> Low Thermal Resistance <0.16°C/W / High thermal conductivity 401W/(m.K)

Copper Substrate and LED Chip Direct Bonding on Cu Base

>>> Special Reflecting Surface

No Ag Plating, Anti-Sulfide, and Low Light Decay.

>>> Ni Coating at the Cu substrate bottom

Anti-Oxidized and SMT Compatible.

COB Multi-chips LEDs

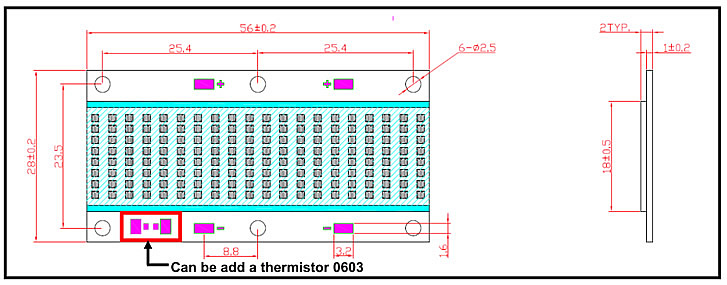

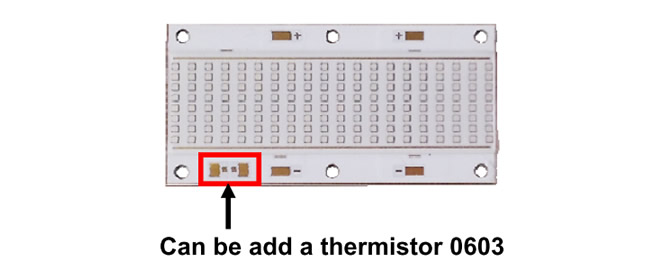

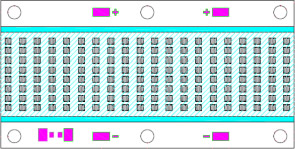

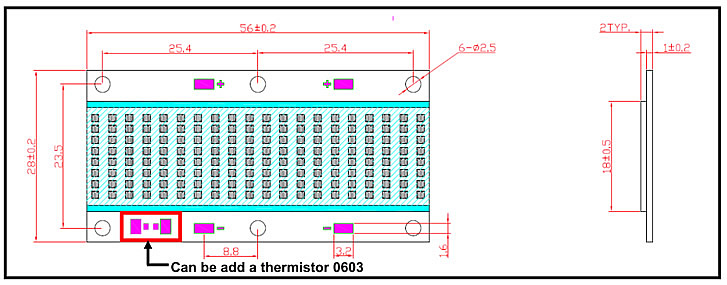

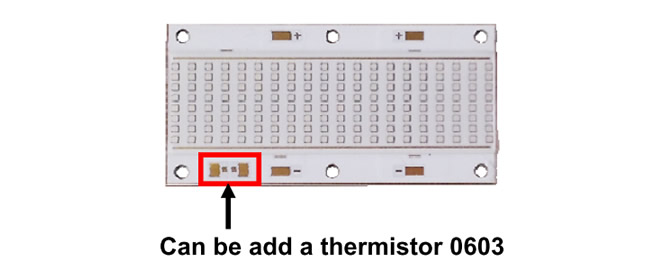

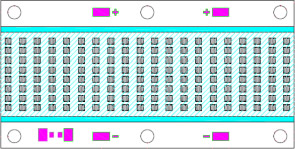

Package Dimensions (mm)

| 1.) |

LED Array : |

8s20p |

| 2.) |

Typical Voltage: |

28V |

| 3.) |

Operating Current: |

6000mA |

Notes: (1) All dimensions are in millimeters. (2) Tolerance is ±0.25mm

Electrical / Optical Characteristics (Ta=25°C)

Optical Characteristics (Ta=25°C)

Parameter |

Symbol |

Wavelength |

Conditions |

Min. |

Typ. |

Max. |

Units |

Irradiance Note[1] |

Ee |

365-370nm |

IF=6000mA |

1.5 |

2 |

- |

W/cm2 |

370-380nm |

2.0 |

2.5 |

- |

380-390nm |

3 |

3.4 |

- |

390-410nm |

4 |

5.5 |

- |

View Angle |

2θ1/2 |

X-Axis |

IF=6000mA |

140 |

150 |

160 |

Degree |

Y-Axis |

120 |

130 |

140 |

Note: [1] Irradiance measured by DYMAX ACCU-CAL 50-LED Meter, and the distance of test is 5 mm.

Over Current Optical Characteristics (Ta=25°C)

Parameter |

Symbol |

Wavelength |

Conditions |

Min. |

Typ. |

Max. |

Units |

Irradiance Note[1]

|

Ee

|

365-370nm |

IF=12000mA

|

- |

4 |

- |

W/cm2 |

370-380nm |

- |

5 |

- |

380-390nm |

- |

6 |

- |

390-410nm |

- |

8 |

- |

Note: [1] Irradiance measured by DYMAX ACCU-CAL 50-LED Meter, and the distance of test is 5 mm.

[2] Recommended water cooling heatsink, with board temperature controlled around 40°C.

Electronic Characteristics (Ta=25°C)

Parameter |

Symbol |

Conditions |

Min. |

Typ. |

Max. |

Units |

Forward Voltage |

VF |

IF=6000mA |

26 |

- |

30 |

V |

Reverse Current Note[1] |

Ir |

VR=5V |

|

|

10 |

uA |

Thermal Resistance

JunctionTo Board |

RthJ-B |

IF=6000mA |

|

0.1 |

|

°C/W |

Temperature

Coefficient of

Forward Voltage |

ΔVF/ΔT |

IF=6000mA |

|

-64 |

- |

mV/°C |

Note: [1] Singe chip VR

Absolute Maximum Rating (Ta=25°C)

Parameter |

Symbol |

Conditions |

Units |

Power Dissipation |

PD |

360 |

W |

Continuous Forward Current Note[1] |

IF |

12,000 |

mA |

LED Junction Temperature |

Tj |

120 |

/°C |

Operating Temperature Range |

Topr |

30℃ To +80℃ |

Storage Temperature Range |

Tstg |

-40℃ To +100℃ |

Manual Soldering Temperature |

Tsol |

260℃±20℃ For 3-5 Seconds |

ESD Sensitivity Note[2] |

ESD |

500V HBM |

Note: [1] Recommended water cooling heatsink, with board temperature controlled around 40°C.

[2] Singe chip ESD.

Optical & Electric Characteristics

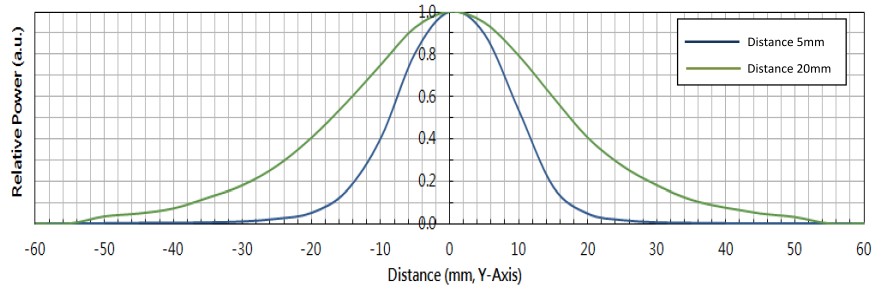

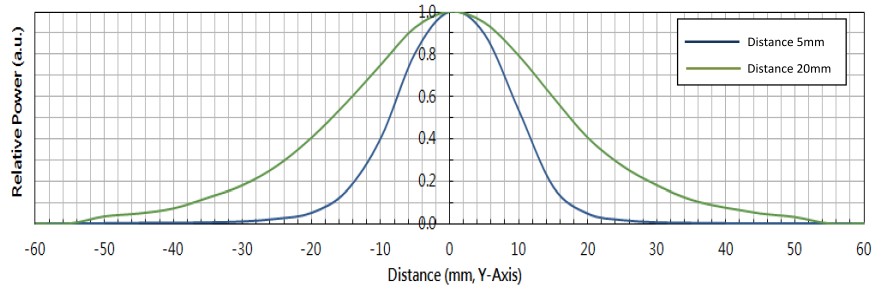

Relative Power vs Distance (at central point ), I F =6000mA

Relative Power vs X-Axis , I F =6000mA

Relative Power vs Y-Axis , I F =6000mA

Relative Power vs Forward Current (IF)

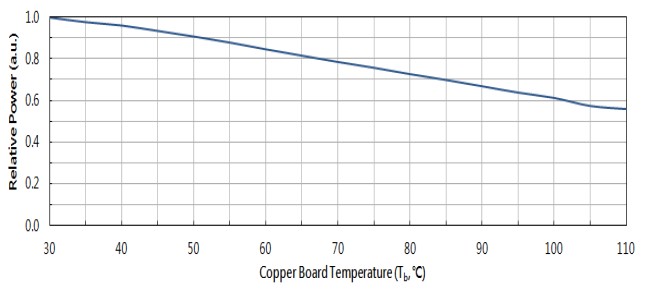

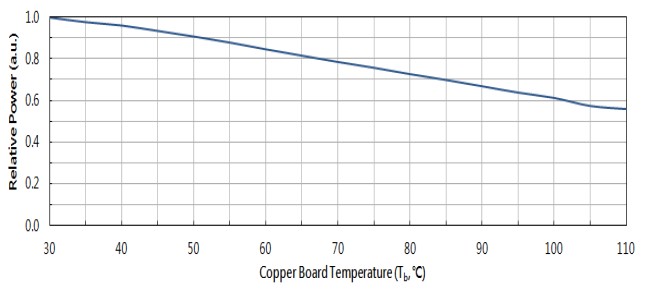

Relative Power vs Board Temperature (Tb )

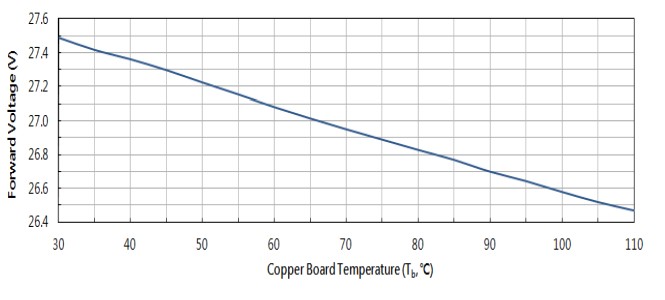

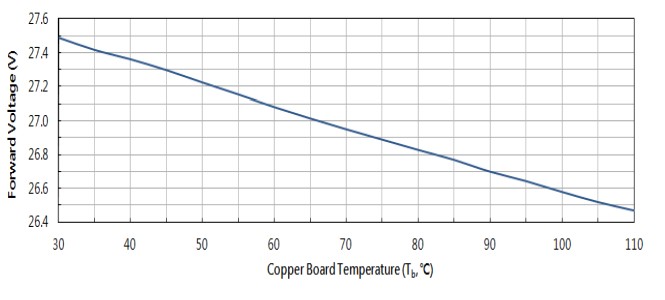

Forward Voltage vs Board Temperature (Tb )

.

UV COB LED Reliability

UC-160-VH (B50,L70) Lifetimes @ IF=6000mA

UV COB LED Spectrum Distribution

.

Assembly Notice

- Do not touch emitting area.

- Do not touch or scratch silicon forming matrix area since it could damage the bonding of LED chipsor wires and cause dead zone.

Don’t touch the surface of Emitter

Don’t touch the surface of Emitter

- Assembly guideline

- Wiring emitter’s anode/cathode pad, then fix emitter with screws onto heat sink.

- Soldering methods

a) Set up the temperature of welding head to 400±10°C when soldering.

b) Put Emitter on a 100±10°C hot plate and set up welding head temperature to 300±10°C

c) Either is OK.

- Wires

- Suggested using strand wires (softer) to connect power, don’t use solid wires.

Used Notice

- In order to avoid absorption of moisture, it is recommended that the products are sotred in the dry box (or desiccators) with a desiccants. Alternatively the following environment is recommended. Storage temperature: 5°C ~ 30°C , Humidity: 60% HR Max.

- Soldering rapidly cooling should be avoided.

- Products should not be assembly on distorted surface of heat sink.

- Products should not contact with any types of fluid, such as water, oil, organic solvents,...etc.

- The maximum ambient temperature should be taken into consideration when determining the operating current.

- This product must be driven by constant power supplier.

- ESD Precautions Static Electricity and surge damages LEDs. It is recommended that wrist bands or anti-electrostatic gloves be used when handing the LEDs. All devices, equipment, and machinery should be properly grounded.

- The appearance and specifications of product may be modified for improvement without notice.

Ordering Information

Color |

Order Code |

Peak

Wavelength (nm) |

Light

Intensity (W/cm2

)@6000mA

|

Min |

Max |

Min |

Max |

UV |

UVA-160-415VH |

410 |

420 |

4 |

6 |

UVA-160-405VH |

400 |

410 |

4 |

6 |

UVA-160-395VH |

390 |

400 |

4 |

6 |

UVA-160-385VH |

380 |

390 |

3 |

4 |

UVA-160-375VH |

370 |

380 |

2 |

2.5 |

UVA-160-365VH |

365 |

370 |

1.5 |

2 |

P.S.

- Caution !! Do not look directly at the UV light , and please wear safety Goggles.

Introduction of accessories

Don’t touch the surface of Emitter

Don’t touch the surface of Emitter